Powder Coat Curing Ovens are essential for transforming powder-coated surfaces into durable, smooth finishes. These ovens use controlled heat to melt and cure powder particles, creating a resilient layer resistant to corrosion, scratches, and UV damage. Designed with insulated chambers, convection systems, and precise temperature controls, modern ovens ensure uniform curing while optimizing energy efficiency. Ideal for automotive, aerospace, and metal fabrication industries, they accommodate various sizes—from compact benchtop units to large industrial setups—making them versatile for high-volume production or specialized projects.

1. Powder Coat Curing Oven Components and Structure

A Powder Coat Curing Oven typically includes an insulated chamber, heating elements (electric or gas burners), airflow systems, and temperature sensors. The chamber, lined with heat-resistant materials, retains thermal energy for consistent curing. Electric models use convection fans to distribute heat, while gas-powered ovens rely on burners and exhaust systems. Advanced units feature programmable controllers for temperature profiling, ensuring adherence to specific curing schedules. Safety components like overheat protection and ventilation safeguards are critical for operational reliability.

2. Applications of Powder Coat Curing Ovens

These Powder Coat Curing Ovens are pivotal in industries requiring high-quality finishes. Automotive manufacturers cure coatings on car parts, while appliance producers use them for refrigerators and washing machines. Metal fabrication shops apply ovens for machinery components, and furniture makers cure decorative items. Compact ovens serve small businesses coating tools or architectural fixtures. Their adaptability to different materials—steel, aluminum, or plastics—makes them indispensable in sectors prioritizing aesthetics and durability.

3. Design Considerations for Powder Coat Curing Ovens

Efficient Powder Coat Curing Oven design balances temperature uniformity, energy consumption, and safety. Proper insulation minimizes heat loss, reducing operational costs. Airflow patterns must eliminate cold spots, critical for even curing. Compliance with safety standards (e.g., OSHA or CE) requires integrating emergency shutoffs and flame detection systems. Gas ovens need robust exhausts to manage emissions, while electric models prioritize circuit safety. Customizable dimensions and heating methods ensure alignment with production needs.

4. How to Choose the Right Powder Coat Curing Oven

Selecting an Powder Coat Curing Oven depends on production scale, budget, and material types. Industrial users prioritize high-BTU gas ovens for fast curing, while small workshops benefit from electric models with lower upfront costs. Evaluate insulation quality and controller precision to avoid under-cured coatings. Energy-efficient designs reduce long-term expenses. Verify certifications and warranties, and consider modular ovens for future scalability.

5. Q&A on Powder Coat Curing Oven Devices

Q: What temperature range is ideal for curing powder coatings?

A: Most powders cure between 300°F–450°F, but always follow the powder coat curing process guidelines for optimal results.

Q: Can curing ovens handle large or irregularly shaped items?

A: Yes, custom-sized chambers and adjustable racks accommodate diverse industrial curing ovens applications.

Q: How do gas and electric ovens compare in efficiency?

A: Gas ovens heat faster, lowering cycle times, while electric models offer precise temperature control for sensitive materials.

Q: What maintenance ensures oven longevity?

A: Clean airflow ducts monthly, inspect heating elements, and calibrate sensors annually to maintain powder coating oven performance.

Q: Are there eco-friendly curing oven options?

A: Look for low-emission burners, energy recovery systems, or powder coating oven price-competitive electric units with renewable energy compatibility.

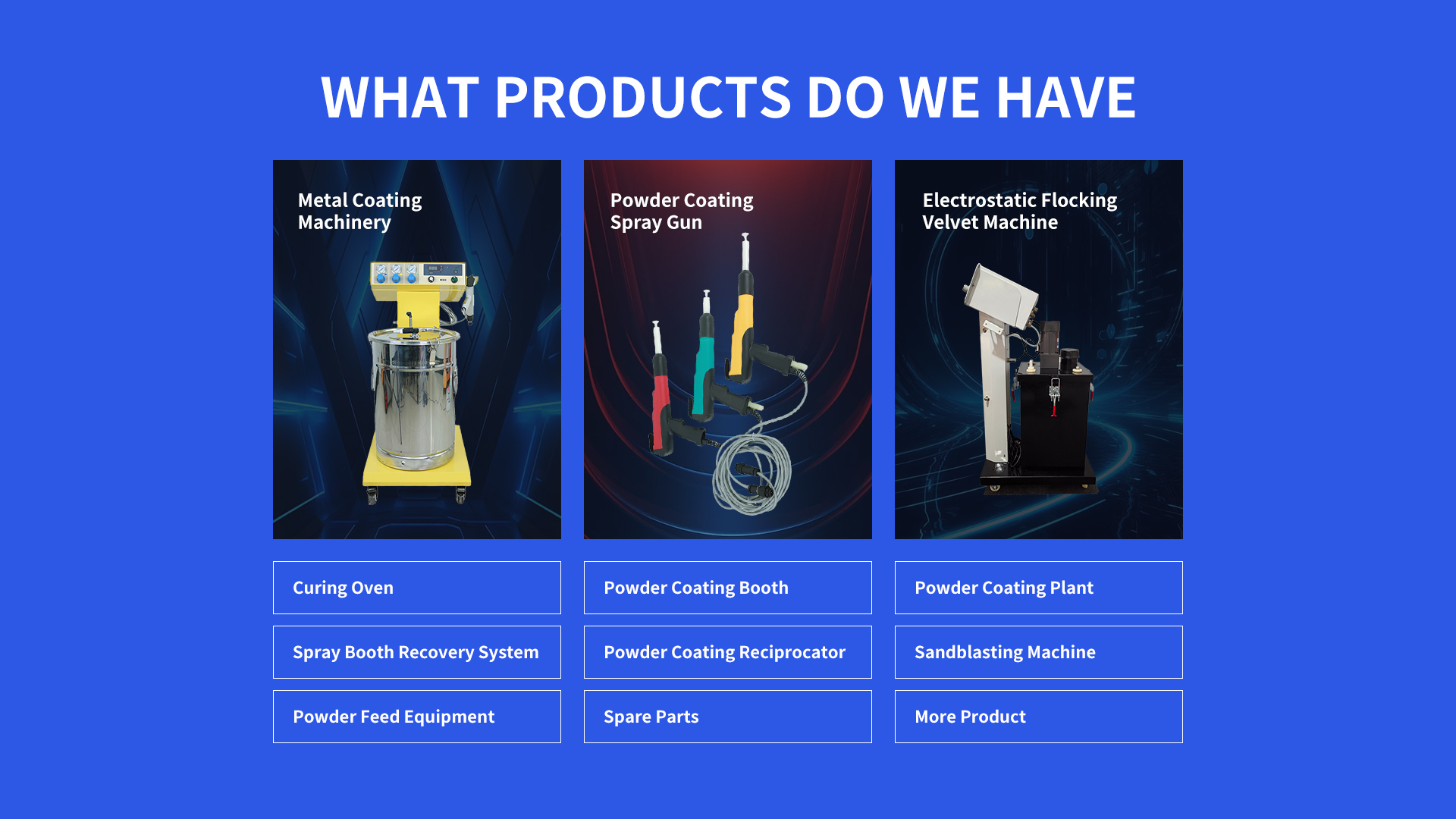

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com